Rolling mill bearings occupies a relatively important position in my country’s rolling mills. Rolling mill bearings often cause mechanical burnout in daily production. How to reduce the number of rolling mill bearings burning, improve the level of rolling mill equipment, and increase the operating rate of rolling mills, especially for rolling mill bearings The cause of the burn was analyzed.

The reasons leading to the failure of rolling mill bearings can be roughly divided into two aspects:

1. Internal reasons, such as bearing quality.

2. External reasons, such as installation, maintenance, and maintenance. In order to find out the reasons, better targeted measures are taken, and it is very important to analyze the causes of the burn.

Analysis of the causes of burning

2.1, assembly problems

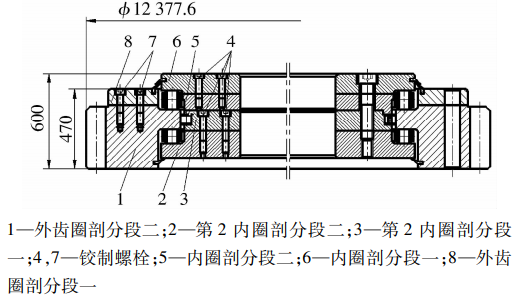

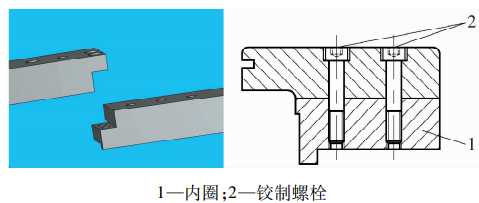

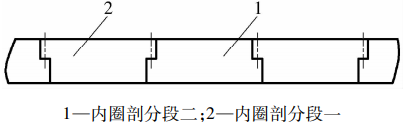

2.1.1. Since the manufacturing precision of the rolling mill is not very high, when the service life is long, the various accessories of the rolling mill will deform to different degrees, and the bearing seat will have a large difference in coaxiality, which makes the bearings at both ends of the rolling mill uneven. Insufficient lubrication is prone to generate high frictional heat, which may cause local pitting or seizure of the bearing. Combining the actual situation of the rolling mill, use cleaning agent before installation, clean the bearing, dry it with compressed air, and then check the roller, cage, and raceway. Use tools to rotate the cylindrical roller bearing. The bearing can be smooth and linear. Rotate to continue using. If the rollers and raceways have dents, pitting, etc., replace them.

2.1.2. The size, geometry and accuracy of the dynamic and static labyrinths are also issues that cannot be ignored that affect the burning of the rolling mill bearings, because the dynamic labyrinth follows the rotation of the roll. If the dynamic and static labyrinths are deformed, the waterproof ring may be affected by a certain local A point of intermittent friction during the rotation process will generate stress concentration locally. When the friction is frequent, a large amount of heat will be generated and transferred to the inside of the rolling mill bearing. When the heat is too high, the grease will not dilute to the outside of the seal ring. Loss, causing the bearing to burn or friction and smoke. Before assembling, check the integrity of the dynamic and static maze, remove the attached foreign matter and impurities, and compare the goodness of the fit to avoid wear caused by processing errors, and replace the ones that cannot be repaired in time.

2.2, insufficient lubrication

As long as there is movement, there must be friction. The most effective measure to reduce friction is to add lubricating materials. Rolling bearings have both fluid friction and sliding friction in motion. Cylindrical rollers are very hard rotating bodies. During operation, the inner and outer rings of the bearing rotate and slide. Therefore, the friction coefficient is very small. A good lubricating film can ensure good lubrication.

However, bearing burnt caused by lubrication problems often occurs during work, mainly due to the problem of oil volume and the method of refueling. At present, the rolling mill grease we use is a compound calcium sulfonate 3# grease with strong adsorption capacity and can form a high-strength oil film. In terms of oil volume, it is required that all the inner rings of the bearing must be coated with grease at the same time during assembly to ensure that the bearing has sufficient lubrication conditions. For a rolling mill that is used for a long time, the lubrication performance will gradually decrease during use and the wear will gradually increase. Regular lubrication should be used, and the lubricating gun of the pressure oil pump should be used for forced lubrication to ensure normal lubrication conditions.

2.3. Foreign body impact

Foreign matter is the so-called foreign impurity, mainly in several aspects:

1. Other impurities brought from grease;

2. Foreign matter enters the bearing during disassembly and assembly;

3. Partial damage caused by the impact of accessories during the assembly process;

4. Water and dust at work. One of the most common is the introduction of grease and foreign matter in the process of disassembly and assembly.

When the diameter of the foreign body is less than the working gap of the bearing, it can be stirred by grease to cause friction and strain on the working surface of the ball, which will cause the bearing to wear and fail in advance; when the foreign body is larger than the working gap, the foreign body will be crushed and a part of it will be embedded in the working surface, causing jam Dead, the fragments not embedded in the working surface will be involved in the grease, aggravate the wear surface of the bearing, cause the temperature of the working surface to rise sharply, and quickly wear the oil film, causing the bearing to burn when running in the dry grinding state. Therefore, strictly controlling the entry of foreign matter into the bearing is an important aspect of our work.

The bearing seal ring is also an important device to prevent water and foreign matter from entering, and it also serves to prevent the leakage of lubricating oil. Because the structure of the vertical rolling mill determines that the roll is rotating, water and impurities can easily pass through the gap between the sets. With the rotation of the roll, it enters the inside of the bearing, which will corrode the lubricating grease and reduce the lubrication effect. This is also the noteworthy part of our work. The sealing facility of the roll head cannot be easily removed.

2.4, overload damage

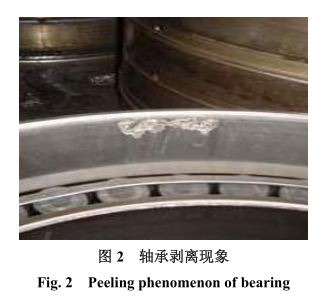

Under overload conditions, rolling bearings generally produce abnormal wear and fatigue damage. Combined with actual production, there are many reasons for bearing damage caused by cyclic load overload. Take the production of channel steel as an example to illustrate. The braking force is much larger than that of round steel, and the probability of bearing burning is also greater. Due to the requirements of the rolling process, some racks have a large amount of reduction, which makes the bearing work under a larger load when it is impacted, resulting in local rolling elements Fatigue cracks are initiated, causing fatigue wear and burning of the bearing.

2.5, the influence of external temperature

Rolling mill bearings are more sensitive to external factors in the long-term high temperature, high speed and frequent impact. Compound calcium sulfonate base 3# grease is suitable for the lubrication of high-load working mechanical bearings. The dropping point is greater than 300℃, the oil separation is about 2%, and the high temperature reversibility does not work. The 1/4 cone penetration difference is small . When the roll is working, due to various reasons, the cooling water cannot provide a good cooling effect, so the temperature of the roll itself is too high and will be transferred to the inside of the bearing. Once the temperature is ≥300 degrees, the grease will slowly become liquid. A large amount of lubricating oil will leak to the outside of the bearing, and the lubrication conditions will drop sharply, causing the temperature of the bearing to rise step by step, and finally causing the bearing to burn. Therefore, in the work, the management of the cooling water of the rolling mill is also an indispensable link to reduce the burning loss of the bearing.