Improve the service life of rolling mill bearings

The failure of the work roll bearing of the cold rolling mill causes the rolling line to stop, reducing the operating rate of the rolling mill, and reducing the output; causing damage to the bearing, the bearing seat and its accessories. Therefore, while absorbing the successful experience of other manufacturers, combined with the actual working conditions of the site, starting from the causes of bearing failure and control measures, bearing quality, bearing management, rolling state of the rolling mill, etc., a set of conclusions is drawn to reduce the consumption of work roll bearings. , An effective measure to improve the service life of the bearing.

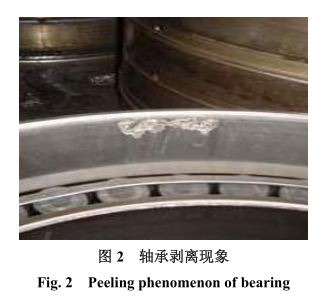

Peel off

When the bearing rotates under a load, the raceway surface or rolling element surface of the inner and outer rings exhibits scale-like peeling due to rolling fatigue, as shown in Figure 2. The peeling of work roll bearings is generally caused by the following factors: excessive load; poor installation (non-linearity), foreign matter intrusion, water ingress; poor lubrication, lubricant discomfort, improper bearing clearance; rust, erosion points, scratches and Development caused by indentation.

Methods to prevent peeling of work roll bearings: check the size of the load and re-study the bearings used; improve the installation method, improve the sealing device; use a lubricant of appropriate viscosity, improve the lubrication method; check the accuracy of the shaft and the bearing box; check the travel Gap.