Types and characteristics of bearing grease

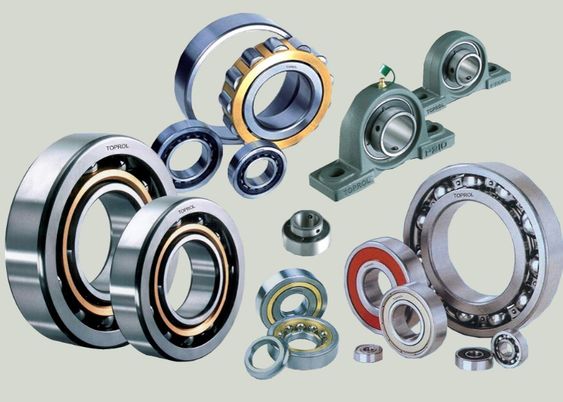

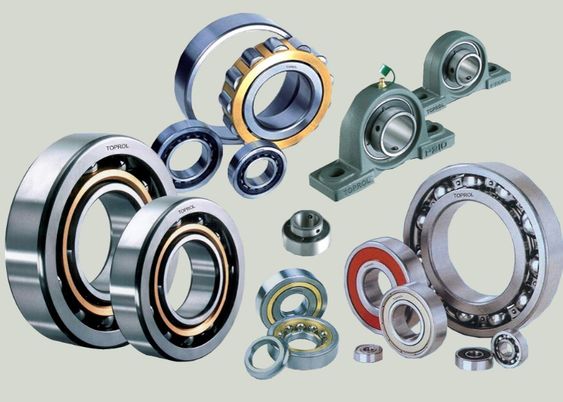

Bearings are commonly used in mechanical equipment. So, what kind of grease should we use for different types of bearings to make them last longer? This article will analyze several common bearing grease types and characteristics.

- Calcium-based grease

Calcium-based grease is a lubricating product made with calcium soap as the main thickener and supplemented by other additives. It has good lubricity, good water resistance, average adhesion, high dropping point, and good high and low temperature resistance. Since calcium-based grease is evolved from soap-based grease, it has all the characteristics of soap-based grease. When used, it is generally relatively viscous and will not easily run off when applied to bearings and other components. It will produce a lubricating film between the metal and the substance.It is especially suitable for the use of some mechanical equipment in environments with high humidity, high temperature or large mechanical vibration. It is widely used in industrial equipment, especially in the lubrication of high-temperature, low-humidity or dust particle environments, as well as high-speed rolling bearings with particularly heavy workloads that require particularly high grease film pressure.For example, this kind of grease is widely used in mechanical equipment such as cotton pickers, cotton balers, and threshing machines in the agricultural machinery industry.

- Lithium-based grease

Lithium-based grease is a versatile lubricating product made with natural fatty acid lithium soap as a thickener and other auxiliary additives. Lithium-based grease is synthesized from a variety of materials such as mineral oil, soap-based thickeners, additives and fillers. It has a soap fiber structure. As the temperature increases and decreases, the molecular structure changes, thus affecting the viscosity and consistency of the grease. Due to its good comprehensive performance, it can meet various bearing lubrication requirements under harsh conditions. Especially when used under conditions such as high temperature, high speed, heavy load and chemical corrosion, it shows its superiority. It can be applied to the lubrication of various types of bearings. This kind of grease is widely used in agricultural machinery such as tractors, automobiles, diesel engines and other mechanical equipment.

- Lithium complex grease

Lithium complex grease combines the advantages of various lithium greases and has the characteristics of high dropping point, good adhesion, extreme pressure and anti-wear, water resistance, and excellent rust prevention. It is blended with lithium complex soap thickener, high viscosity refined oil and softener. Suitable for lubrication of various bearings under conditions such as high temperature, high speed, high speed and humidity.Due to its excellent performance, it has been widely used in some mechanical industry fields. The lubrication of chains and gears used in steel plants is one example.

- Extreme pressure calcium-based grease

The characteristic of this kind of bearing grease is that it can wash away worn metal chips to a certain extent, reduce the direct wear effect of solid impurities on the bearing steel surface, and improve the wettability of the bearing steel surface, making the steel surface less likely to be scratched. thorns, thereby ensuring a longer-lasting and better self-lubricating effect between the steel surface and the journal, and helping to reduce mechanical noise and ensure low-noise working conditions of mechanical equipment.It is suitable for coating the surface of castings before leaving the factory to eliminate impurities and tiny convex parts remaining on the surface of the parts during casting and prevent corrosion, making the castings easy to assemble and reduce friction. In addition, it is also suitable for the lubrication and flushing of double-row radial spherical roller bearings in textile machinery coiler bearings and other parts in the machinery industry that require waterproofing, rust prevention and a certain degree of adhesion.

- High temperature bearing grease

High-temperature bearing grease should be used for bearing parts in mechanical equipment that are often exposed to high temperatures.Generally speaking, high-temperature grease is generally made of fully synthetic base oil and sulfonate thickener at working temperatures below 260 degrees. It is used on bearings working at low and high temperatures in harsh environments (generally more than 150 degrees). It is a high-temperature bearing) and is also suitable for the lubrication and protection of motor parts in the aerospace field. Currently, there are various types of high-temperature greases on the market. When choosing, you should choose the appropriate production raw materials according to the industrial and mining conditions and environmental requirements. The best product is suitable for your own use. For bearings working under high-speed operating conditions, the viscosity of the selected grease should be small and the fluidity should be good to ensure that the resistance is small when the bearing is running. The friction on the bearing is small, which can significantly reduce mechanical noise and save energy; otherwise, the resistance increases. Increased friction will accelerate bearing wear and shorten service life.