The Importance of Bearing Clearance

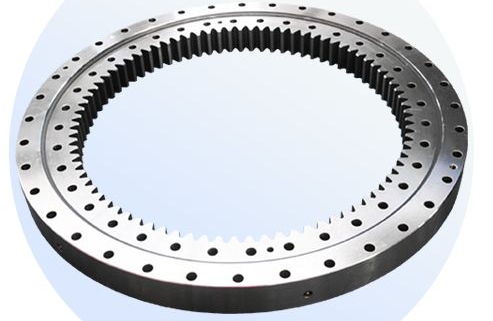

Bearings are an important part of mechanical equipment. They carry out the key tasks of rotation, support and shock absorption. In this process, bearing clearance – the space between the inner and outer rings of the bearing – plays a decisive role. While the concept may seem simple, the presence of clearance can have a profound impact on bearing performance, life and stability.

- Basic concept of bearing clearance

Bearing clearance, also known as preload clearance, refers to the gap between the inner and outer rings of the bearing under no load conditions. This clearance is critical to maintaining the bearing’s rotational accuracy and reducing friction. It provides the bearing with moderate elastic deformation space, helping to maintain shaft concentricity while allowing certain vibration and temperature changes.

- The importance of bearing clearance

1.Mechanical properties: Bearing clearance is critical to the rotational accuracy and stability of the bearing. Excessive clearance may cause friction and heat, thereby reducing bearing life. Proper clearance allows the bearings to operate smoothly, reduces vibration and noise, and improves the overall performance of the machine.

2.Durability: Bearing clearance directly affects the fatigue life of the bearing. Excessive clearance will increase friction and temperature rise, which will accelerate bearing wear and shorten the service life of the bearing. Appropriate clearance can extend the service life of the bearing and improve the overall durability of the equipment.

3.Vibration control: Proper clearance helps reduce bearing vibration and improves equipment stability. This is especially important for equipment that requires high precision and stability, such as precision machine tools, medical equipment, etc.

4.Temperature control: Bearing clearance is closely related to temperature. Excessive clearance will cause friction to generate heat, which will affect the overall temperature distribution of the equipment. The appropriate clearance helps control the temperature and ensure the normal operation of the equipment.

5.Maintenance costs: The stable operation of bearings can reduce the frequency of repair and replacement of bearings, thereby reducing the cost of equipment maintenance. Excessive clearance may cause premature bearing wear, increase the need for repairs and replacements, and thus increase maintenance costs.

- How to measure bearing clearance

In order to ensure the normal operation of the bearing, we need to regularly measure the clearance of the bearing. Typically, we use a radial clearance adjustment device (RCTA) for measurement. This method adjusts the clearance by changing the preload to ensure the best performance of the bearing.

- How to adjust bearing clearance

The method of adjusting bearing clearance varies depending on the bearing type and manufacturer. Usually, we can make adjustments manually or automatically. Manual adjustments usually require the aid of tools such as wrenches and screwdrivers. Automatic adjustment usually relies on some specific devices and methods, such as automatic spherical roller bearings.

Bearing clearance plays a vital role in the operation of bearings. It not only affects the performance and life of the bearing, but is also directly related to the overall stability and durability of the mechanical equipment. Therefore, correctly measuring and adjusting bearing clearance is the key to ensuring the normal operation of mechanical equipment. Appropriate bearing clearance is the guarantee for the long-term stable operation of our equipment.