Performance characteristics and application areas of stainless steel bearings

As an important mechanical component, stainless steel bearings are widely used in various industrial fields, such as automobiles, aerospace, energy, medical equipment, etc. Its outstanding performance and durability make it the first choice for many critical applications. This article will introduce in detail the main performance characteristics of stainless steel bearings.

- High strength and corrosion resistance

The main material of stainless steel bearings is stainless steel, an alloy with high strength and corrosion resistance. The strength of stainless steel allows it to withstand high loads and frequent rotational movements, which is critical in applications that require strong pressure and impact. In addition, the corrosion resistance of stainless steel allows it to maintain excellent performance in various environments, including humidity, high temperature, corrosive chemicals, etc.

- Good friction performance

Stainless steel bearings have excellent friction properties, which can effectively reduce energy loss and improve mechanical efficiency. Its friction coefficient is usually low and changes little under different environmental conditions, which allows the bearing to maintain stable performance under various working conditions.

- Higher speed capability

Stainless steel bearings can withstand higher rotational speeds, which is critical for applications requiring high-speed rotation. This allows the bearing to achieve high performance in a compact space while also reducing noise and heat.

- Long service life

Another important feature of stainless steel bearings is their long service life. Due to their excellent durability and high strength, stainless steel bearings are often able to withstand high loads and frequent rotational movements without premature wear or failure. This significantly reduces maintenance costs and improves the overall performance and reliability of the equipment.

- Environmental protection and sustainability

Another advantage of stainless steel bearings is the environmental friendliness and sustainability of their production. Stainless steel is a recyclable material, which makes equipment using stainless steel bearings easier to recycle and dispose of after its life cycle, reducing the environmental impact.

Stainless steel bearings are widely used in various fields due to their excellent performance and long-term durability. From industrial production to daily life, from high-tech equipment to traditional manufacturing, stainless steel bearings are everywhere.

- Manufacturing industry

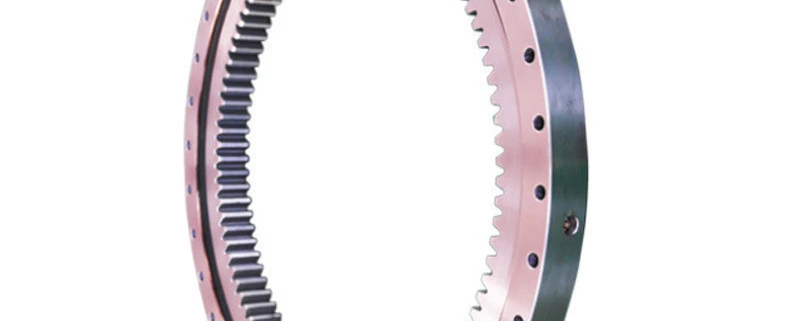

In the manufacturing industry, stainless steel bearings are particularly widely used. Whether it is machinery and equipment in heavy industry, such as excavators and rolling mills, or small equipment in light industry, such as sewing machines and coffee machines, stainless steel bearings play an important role. They perform well and are durable under high loads and high frequency rotations.

- Transportation

The transportation field is also an important application place for stainless steel bearings. In the automobile manufacturing industry, stainless steel bearings are used in key parts such as steering gears and wheel bearings, which greatly improves the performance and stability of the automobile. At the same time, the use of stainless steel bearings in subways, trains and other means of transportation has also improved their operating efficiency and reliability.

- Medical equipment

In the medical field, stainless steel bearings are ideal for medical devices due to their unparalleled resistance to corrosion and wear. For example, orthopedic surgical instruments, wheelchairs, walkers, etc. all require bearings to transmit power. The application of stainless steel bearings on these devices greatly improves their service life and safety.

- Electronic products

With the development of science and technology, the application of stainless steel bearings in electronic products is becoming more and more common. From smartphones to computers, from game consoles to electronic watches, stainless steel bearings can be seen. They provide smooth rotation and precise control of these devices, enhancing the user experience.

- Agricultural machinery

In the agricultural field, stainless steel bearings also play an important role. Stainless steel bearings are used in key parts of agricultural machinery such as tractors and harvesters, which improves the efficiency and durability of the machinery and reduces the cost of agricultural production.

- Sports equipment

In the field of sports equipment, stainless steel bearings are also a major trend in the future. High-end sports equipment such as skis and golf clubs have begun to use stainless steel bearings. They provide better control and stability, allowing athletes to perform better in competitions.

- Underwater equipment

In underwater operations, stainless steel bearings also play an important role. Diving equipment, underwater detection equipment, etc. all require bearings to transmit power. The corrosion resistance and stability of stainless steel bearings under water make them perform well in underwater operations.

In summary, stainless steel bearings have penetrated into various fields with their excellent performance and long-term durability. Whether it is heavy industry, light industry, transportation, medical equipment, electronic products, agricultural machinery or sports equipment, stainless steel bearings provide strong support for the development of various fields with their excellent performance and stability. With the advancement of science and technology and the expansion of application fields, we can foresee that the application fields of stainless steel bearings will continue to expand, and their importance will become increasingly prominent.