What is the difference between rolling bearings and slewing bearings?

Rolling bearings and slew bearings are both types of bearings. They have many similarities in application, but there are also some obvious differences between them. Rolling bearing is a mechanical component that bears load during rolling motion and is widely used in various mechanical equipment. A slew bearing is a special type of bearing with a combined radial and axial load capacity, often used to support rotating shafts or rotary-linear motion hybrids. The two mainly differ in the following aspects:

- Structural characteristics

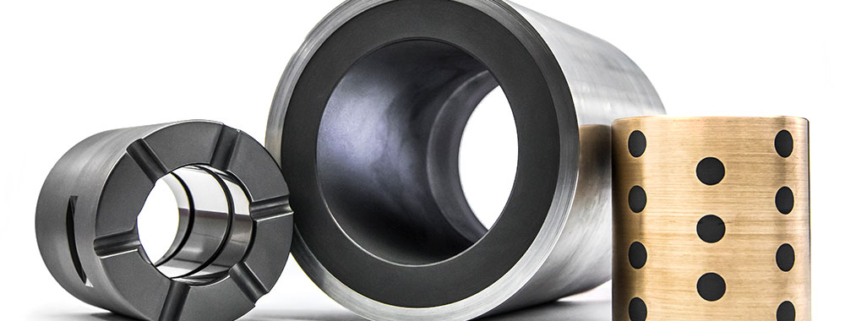

The structural features of rolling bearings include balls, inner rings, outer rings, cages and other components. The inner ring is closely matched with the shaft, and the outer ring is matched with the bearing seat. The cage separates the balls and distributes them evenly. Rolling bearings have the advantages of small friction coefficient, low vibration and noise, but they also have maintenance requirements.

The structural features of slew bearings include outer rings, inner rings, rolling elements (balls or rollers) and cages. The outer ring can be an integral structure or a segmented structure, and the inner ring is closely matched with the shaft. Slewing bearings can bear both radial and axial loads, and have high rotation accuracy and axial load-bearing capacity. Slewing bearings have a long service life and are suitable for high-speed, high-precision mechanical equipment.

- Application scope

The application range of rolling bearings is very wide, involving almost all types of mechanical equipment, such as machine tools, automobiles, aircraft, ships, etc. There are many types of rolling bearings, and the appropriate bearing type can be selected according to different loads, speeds, accuracy and speed ranges.

The application range of slew bearings is relatively narrow and is mainly used in robotic arms, packaging machinery, machine tool equipment, plastic machinery, steel rolling equipment and other fields. The characteristics of high precision, high rigidity and high load-bearing capacity of slew bearings make them an indispensable part of these high-precision mechanical equipment.

- Load characteristics

The load properties of rolling bearings are generally radial load or axial load, but some special types of rolling bearings such as angular contact ball bearings can withstand combined radial and axial loads. The nature of the load depends on the bearing’s structural design and application.

The load properties of slew plate bearings are mixed radial and axial loads. This load characteristic gives slew plate bearings unique advantages in supporting rotating shafts or rotation-linear motion hybrids.

- Rotation accuracy

The rotation accuracy of rolling bearings depends on their manufacturing quality, the function of the cage, and the maintenance during use. Under continuous load, the rotation accuracy of rolling bearings is prone to change.

The rotation accuracy of the turntable bearing is relatively high, and it can maintain high accuracy even under high-speed rotation. This is because the structural design of the slew bearing helps reduce friction and vibration, thereby maintaining stable rotation accuracy.

There are obvious differences between rolling bearings and slew bearings in terms of structural characteristics, load characteristics, and rotation accuracy. Rolling bearings are suitable for various mechanical equipment and have the advantages of small friction coefficient, low vibration and noise, but they require regular maintenance. Slewing bearings are suitable for high-precision mechanical equipment that supports rotating shafts or rotation-linear motion hybrids. They have the characteristics of high precision, high rigidity and high load-bearing capacity. When selecting bearings, the most suitable bearing type should be selected based on the characteristics and requirements of the specific application.