Do you really understand bearing steel?

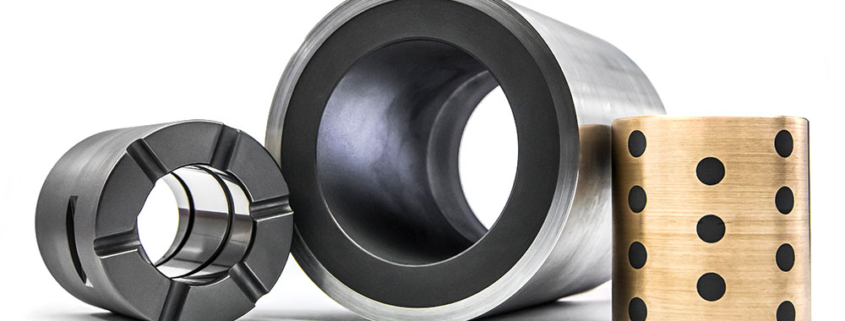

Bearing steel is the steel used to make bearings. Mainly divided into high carbon chromium bearing steel, carburized bearing steel and medium carbon bearing steel. Among them, high-carbon chromium bearing steel has good comprehensive properties and has the largest output. It has good cutting performance after spheroidizing annealing, high hardness and good wear resistance after quenching and tempering. Widely used in bearing manufacturing.Carburized bearing steel is used for high-load, high-speed bearings, such as automobiles, tractors, etc.; medium carbon bearing steel is used for manufacturing rolling bearings. In addition, bearing steel also includes stainless steel bearing steel, etc. These materials have high strength, wear resistance, corrosion resistance and other properties, allowing the bearings to operate normally in various harsh environments.

Bearing steel is a specialty steel used to make bearings and similar parts. Widely used in machinery industry. Bearing steel has the following outstanding performance characteristics:

1.High wear resistance: Since bearings are subject to extremely severe friction and wear, the bearing steel must have high wear resistance. The high wear resistance of bearing steel is due to the fact that the steel contains a large number of carbides, nitrides and other hard points. These hard spots form a protective film that effectively reduces friction and friction between the bearing and other contact surfaces. wear and tear.

2.High hardness: The hardness of the bearing steel is required to be around 60HRC so that it can withstand larger loads during work.

3.High strength: Bearing steel needs to be strong enough to resist stresses such as impact, vibration and bending during operation.

4.Good toughness and corrosion resistance: Bearing steel also needs to have good toughness and corrosion resistance to extend its service life.

To sum up, the performance characteristics of bearing steel are high wear resistance, high hardness, high strength, good toughness and corrosion resistance. These properties make bearing steel an ideal material for manufacturing bearings and similar parts.

The production of bearing steel requires special processes. First, raw steel is melted into molten steel in a steel-making furnace, and then different alloying elements are added to adjust the composition and properties of the steel. Next, molten steel is poured into the mold and solidifies to form an ingot.The steel ingot is then heated to a certain temperature and pressed through a rolling mill into the desired product shape, such as steel plate or steel bar. Finally, the steel is heat treated to improve its hardness and wear resistance to meet the requirements of bearing use. This production process requires precise control of the composition and properties of the steel, as well as strict control of temperature, pressure and other factors during the production process to ensure the quality and performance of the bearing steel.

Only by selecting the appropriate bearing steel material can the safe operation of mechanical equipment be ensured. When choosing bearing steel materials, the first thing to consider is your own application scenario. If the equipment needs to withstand high loads and high-speed rotation, it is necessary to choose bearing steel with high hardness and good wear resistance. If the equipment needs to run continuously for a long time, it is necessary to choose bearing steel with high corrosion resistance and oxidation resistance. In addition, the temperature and humidity of the use environment must also be considered to select bearing steel materials that adapt to these conditions. Only by correctly selecting the bearing steel material that suits your needs can you ensure safe and stable operation of the equipment.