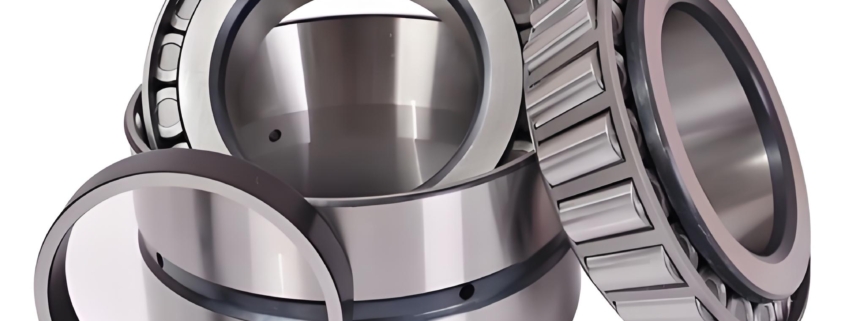

Руководство по выбору конических роликоподшипников и индивидуальные услуги Luoyang INNO Bearing

В процессе механического производства и обслуживания оборудования правильный выбор конических роликовых подшипников имеет решающее значение для производительности и срока службы оборудования. Имея многолетний опыт работы в данной отрасли, компания Luoyang Inno Bearing Co., Ltd. предоставляет клиентам профессиональные рекомендации по выбору конических роликовых подшипников и индивидуальные услуги, чтобы помочь клиентам решить проблему выбора подшипников и удовлетворить различные потребности в применении.

При выборе конических роликовых подшипников в первую очередь необходимо учитывать условия нагружения. В том числе размер, направление и характер радиальных и осевых нагрузок (например, статические нагрузки, динамические нагрузки, ударные нагрузки и т.д.). Как правило, конические роликоподшипники могут одновременно выдерживать большие радиальные и однонаправленные осевые нагрузки. Если во время работы оборудования осевая нагрузка велика, необходимо выбрать подходящий угол контакта и модель, чтобы обеспечить грузоподъемность подшипника. Техническая команда Luoyang Inno Bearing Co., Ltd. может рекомендовать клиентам наиболее подходящую модель конического роликового подшипника на основе подробных данных о нагрузке, предоставленных клиентом, и использовать профессиональные методы расчета для обеспечения стабильной работы подшипника в реальных рабочих условиях.

Во-вторых, скорость также является важным фактором при выборе. Максимально допустимая скорость конических роликовых подшипников разных типов и спецификаций отличается. Высокоскоростное оборудование предъявляет повышенные требования к точности подшипников, смазке и отводу тепла. В конических роликовых подшипниках, производимых компанией Luoyang Inno Bearing, используются высококачественные материалы и передовые производственные процессы. Обеспечивая высокую грузоподъемность, они могут адаптироваться к различным требованиям скорости. Кроме того, компания предоставит клиентам соответствующие решения по смазке и отводу тепла в зависимости от скорости работы оборудования, чтобы уменьшить износ подшипников и продлить срок службы.

Помимо нагрузки и скорости, не следует игнорировать и рабочую среду. Например, температура, влажность, пыль, агрессивные среды и т.д. влияют на работу подшипников. В условиях высокой температуры необходимо выбирать подшипники из термостойких материалов и использовать подходящую смазку; в условиях пыли и агрессивных сред необходимо усилить защиту подшипников от уплотнений. Luoyang Inno Bearing предлагает различные конические роликовые подшипники со специальным дизайном и процессами обработки для различных рабочих сред, таких как специальная обработка поверхности, оптимизация структуры уплотнения и т.д., чтобы гарантировать, что подшипники могут по-прежнему надежно работать в суровых условиях.

Для некоторых клиентов с особыми потребностями Luoyang Inno Bearing Co., Ltd. также предоставляет услуги по индивидуальному заказу. Компания может осуществить индивидуальное проектирование и производство конических роликовых подшипников в соответствии со структурой оборудования клиента, требованиями к производительности и т.д. От размера, материала до внутренней структуры подшипника, он может быть настроен в соответствии с потребностями клиента, чтобы предоставить клиентам уникальные подшипниковые решения. R&D и производственные команды компании имеют богатый опыт и сильную техническую силу, и могут быстро реагировать на потребности клиентов, обеспечивать своевременную доставку продукции и предоставлять комплексное послепродажное обслуживание.

Выбор конических роликовых подшипников требует всестороннего рассмотрения множества факторов, и компания Luoyang Inno Bearing Co., Ltd., обладающая профессиональными технологиями и богатым опытом, может предоставить клиентам всестороннее руководство по выбору и высококачественные индивидуальные услуги. Выбор конических роликовых подшипников Luoyang Inno Bearing означает выбор надежности, эффективности и профессионализма, что сделает работу вашего оборудования более стабильной, а производство более эффективным.